Steel coil Crosscut production line

1.1、Overview:

The equipment mainly adopts the technological process of "feeding → uncoiling → precise leveling and sizing → transition table → shearing → simple blanking". The processed products are required to meet the corresponding national standards.

1.2、Unit usage and process flow:

1.2.1、Unit purpose:

This equipment is a special shearing equipment for processing coils into the size required by customers and neatly stacking them by unwinding, leveling and measuring transverse shears. Its main working host is composed of uncoiling machine, precision straightening machine, shearing, palletizing and other components。

1.2.2、Process flow:

The coil is hoisted from the coil storage to the coil preparation table by the driving carriage, and then sent to the coil of the unwinder by the coil trolley. The coil is expanded to make the coil solid on the coil, remove the strap, and use the unwinding knife , Introduce the belt head into the pinch feeding device, convey it to the strip steel straightening machine for leveling, shear, the sheared sheet is sent to the stacker for stacking by the conveyor, and then transferred to the packaging, weighing, storage and other processes , Waiting for shipment.

2、The main technical parameters of the unit:

2.1 Raw material parameters:

1.1. Raw materials and strength: q235, Q195 not exceeding 6mm hot rolled steel

2.Steel plate thickness: 0.8~6mm

3.Steel plate Width: 800~1250mm

5.Coil ID : Ø610mm-760mm

6.Coil OD : Ø1000mm~Ø1800mm

7.Coil weight: max20t

2.2 Finished product parameters:

1. Length tolerance : ≤±2mm/2m

2. Diagonal tolerance after cutting:≤±2mm/2m

3. Flatness: ≤±2mm/㎡

4.Cutting length: 6 000mm

5.Heigth: 400mm(With tray height 550mm)

6. Stacking weight: Max10000kg

2.3 Unit parameters:

1.Unit elevation: 900mm above ground

2. Running speed: V≤20m/min(Adjustable according to shearing material length)

4.Unit footprint: 15m×5m(Length X width)

6.Running direction: User provided

2.4 Environmental conditions:

1. Ambient temperature: -15~40℃

2. Relative humidity: ≤90%

3. Working power: AC440V±10%,50HZ ±2% Three-phase four-wire system

4. Compressed air pressure: 0.6-0.8Mpa

5. Compressed air consumption:≈1m³/min

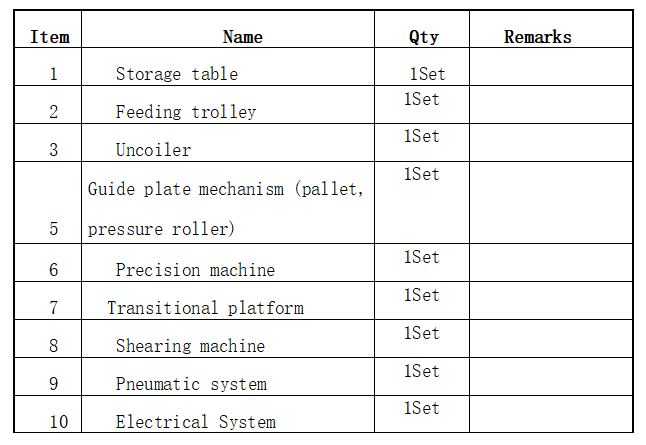

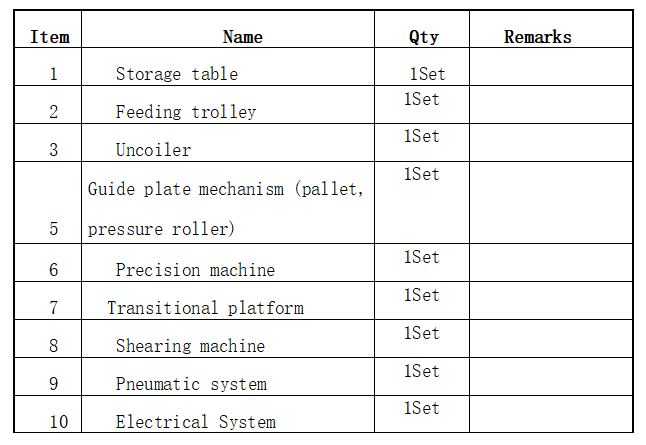

2.5 Including device range