Double lines and high speed type automatic packaging system

Main standard features

The DXD-2500 machine can run two bags simultaneously. These machines are designed to equip with the 14 and 16 head weight balance. Having two machines in one frame saves space and cost. only 11.2sq.m. Of floor space is needed for the high speed weighing and packing line, and 5m for overall height equipped with a 14-head weight balance.

Using Japan PLC programmer and touch screen, which is easy to predominate running state, trouble state, operation order, and production state. Using AC Alternating Current servo motor to control film pulling. In the cause of film pulling it is stable, and with high accuracy orientation. Lubricating is not needed it is possible to revise parameter and adjust position without stopping the machine.

Using temperature controller to keep temperature of hot seal unaltered to use dent form sealer to seal film highly BH series is equipped with automatic trouble alert to find product to be cut by knife, safety door not to be closed, film wrapping not to run exactly and film to be used up.

Option:

Gas flushing (Air or Nitrogen gas), Tear notch, Gusseted device, Air expeller, Hole punch device, Polyethylene sealing system, vacuum bag system.

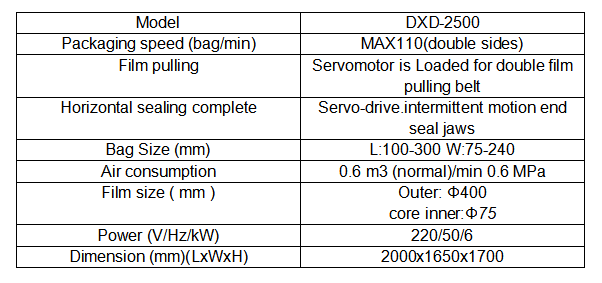

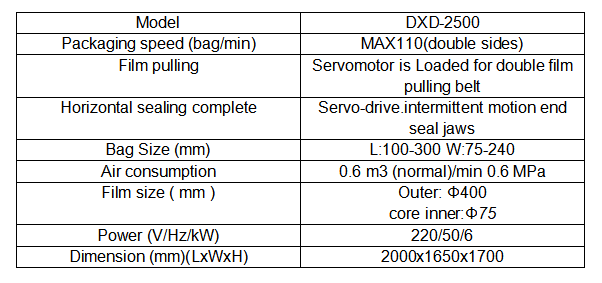

Main technical data: