-

- Search Products & Suppliers

- Product Directory

- Supplier Discovery

- Video Channel

- Post Sourcing Request

- Sourcing Solutions

- Source from Industry Hubs

- Customize Your Products

- MEI Awards-Winning Products

- Smart Expo

-

- Service

- New User Guide

- Star Buyer

- Product Alert

- Supplier Audit Report

- Meet Suppliers

- Online Trading

- Contact Us

- Quick Links

- My Favorites

- Recent Visit History

Automatic intelligent parallel concentrator

| US $0.00 / 件 | | 0 件 (Min. Order) |

| Brand: | |

|---|---|

| : | |

| : | |

| : | |

| Quantity: | |

| Area: | 天津 |

| Expiry: |

Long-term

|

|---|

Contact Supplier

Basic Info.

Product Description

Automatic intelligent parallel concentrator

There are four types of automatic nitrogen blowing parallel concentrators: FULL AUTO VAP-12, FULL AUTO VAP-24, FULL AUTO VAP-30 and FULL AUTO VAP-60. The unique nitrogen management scheme, exhaust gas removal technology and vortex nitrogen purging fully reflect the safe and rapid concentration effect on the premise of ensuring the consistency of concentration. The appearance design is reasonable, and the 10-inch LCD true color touch screen is used as the operation area, with safety protection such as time, end point conditions, reminders and prompts.

The automatic adjustment function of the nitrogen mouthpiece angle can ensure the sample recovery rate and parallelism, and achieve advanced intelligentization and high efficiency. Using 10-inch high-definition touch screen control, the nitrogen blowing angle and nitrogen blowing pressure are automatically adjusted by the program, each channel can be independently controlled and equipped with an independent liquid level sensor to achieve precise volumetric and provide a variety of working modes to meet different concentrations need.

Application field

Environmental monitoring Soil, water quality, sediment, atmosphere, etc.

Agricultural product testing Pesticide residues, veterinary drug residues, etc.

Food safety Additive content, organic high-risk substances, etc.

Drug analysis Chinese herbal medicine pesticide residues (2341 method), etc.

Performance advantage

Ø 1. With Internet of Things function, remote monitoring (optional item).

Ø 2. It can concentrate 12/24 samples at the same time, and each channel can be controlled independently, compatible with up to 60 bits of 10ml.

Ø 3. Compatible with large and small volume concentration cups, and independent sensors automatically set the volume.

Ø 4. The PID method is used for precise temperature and pressure regulation, with high accuracy and good parallelism.

Ø 5. The nitrogen blowing angle is automatically adjusted, and the multi-stage program is automatically boosted.

Ø 6. 10-inch high-definition color touch screen, real-time display of concentrated operation parameters and temperature operation curve.

Ø 7. A variety of working modes are available to meet different application requirements.

Ø 8. The graphical interface, clear and intuitive, optimizes the human-computer interaction experience.

Ø 9. PID temperature control method, the temperature control accuracy is up to 0.1 ℃, which can stabilize the constant temperature water bath or complete the accurate temperature change control according to the setting.

Ø 10. Adopt gas vortex technology to speed up solvent evaporation and complete concentration more quickly and efficiently.

Ø 11, 30 and 60 positions 10ml 10 air blowing needle nozzles per channel, can concentrate up to 60 samples or 30 samples at the same time.

Ø 12. Each nitrogen purging channel can be opened or closed through an independent solenoid valve.

Ø 13. The fluid distribution technology is used to keep the nitrogen flow rate of each branch blowing ☐ consistent, and fully meet the uniform and uniform requirements of the concentration conditions.

Ø 14. The front-end lateral air purging can effectively remove the vapor of the evaporating reagent and reduce the saturated vapor pressure above the concentrating tube, thereby increasing the concentration speed.

Ø 15. It can provide users with customized sample rack services within a certain range, so that the concentrator can meet the needs of different users to the greatest extent.

Ø 17. For the direct concentration of various collection bottles, it can be used with various instruments and equipment.

Ø 18. Open the top cover during the enrichment process, and the instrument will automatically turn off the gas source. After the operator completes the manual operation, click the start button to confirm the continued enrichment, and the buzzer will alarm when the instrument is opened.

Ø 19. When the artificial temperature exceeds the set temperature by 2℃, the instrument will give an alarm prompt, and the alarm temperature can be set as required.

Ø 20. Double-glazed windows, visible on three sides, fully satisfy users to observe the concentration effect and status at any time.

Ø 21. The configured reagent pump can regularly and quantitatively flush the side wall of the concentrated cup to improve the recovery rate.

l Compatible with large and small sample concentrating tubes, optional 250ml, 200ml, 100ml, 10ml and other concentrating tubes of different specifications, all of which are designed with a narrow mouth tube body

l Each sample channel is equipped with an independent infrared fiber optic liquid level sensor, which can be selected from 1.0ml, 0.75ml, 0.5ml and other constant volume volumes, and has an evaporation-to-drying mode, and automatic sound and light prompts when the concentration end point is reached (100ml/bit and above).

l Self-contained lid-opening and hovering function: nitrogen blowing stops automatically when the upper lid of the concentrator is opened, and automatically returns to the state before the lid is closed after the lid is closed, which is convenient for users to start and stop at any time and increase or decrease samples at any time.

l When concentrating, the nitrogen blowing angle is automatically adjusted by the motor, the angle range: 45-90 °C, to ensure that the contact area between the nitrogen and the sample liquid surface is sufficient, improve the concentration efficiency, and avoid the rapid reduction of the energy consumption ratio when the angle is too small.

l With the function of gradient program boosting, the nitrogen blowing pressure can be automatically adjusted with the concentration process. Pressure control accuracy: ±0.5psi, pressure control range: 1~72.5psi, pressure response time: no more than 2s.

l The remote Internet of Things function can be upgraded, the concentration status is displayed in real time on the remote client, and the notification is automatically pushed after completion, without the need for personnel on duty, improving the efficiency of laboratory work.

l The front end of the concentrator is designed with a visible glass window and is equipped with an intelligent sound and light display system.

l The concentration chamber is sealed and equipped with a powerful exhaust device and an intelligent quick-plug drainage device, which is convenient and quick.

l Display the concentration operation parameters in real time, save and recall a variety of concentration methods at any time, and call the preset concentration method with one key, which can effectively ensure the reproducibility of the operation.

l Provide four working modes: constant volume mode, timing mode, mixed mode (constant volume + time) and manual mode, which can meet the needs of different types of applications.

l After the anti-corrosion and rust coating process, it can further improve the durability of the instrument and prolong the service life.

l Support 12 or 24 channels for concentration at the same time, and any sample channel can be started and stopped at any time through the touch screen interface.

controlling software

Server-side remote encrypted data storage, operation parameter setting and download, the operation is more in line with the habits of office workers;

Adopt 10-inch high-definition color touch screen control, graphical and intuitive display, free switch between Chinese and English interfaces;

Four working modes: there are constant volume mode, timing mode, mixed mode and manual mode for users to choose to meet different application needs;

The interface displays information such as nitrogen blowing angle, nitrogen blowing pressure, water bath temperature and concentration time in real time, and supports online editing and saving of concentration parameters;

Each sample channel is independently controlled, and any channel can be started, paused or stopped at any time, and the operation is flexible and convenient.

Environmental Testing - Application Standards

soil and sediment

HJ 890-2017 Determination of polychlorinated biphenyl mixtures by gas chromatography

HJ 834-2017 Determination of semi-volatile organic compounds-Gas chromatography-mass spectrometry

HJ 805-2016 Determination of Polycyclic Aromatic Hydrocarbons Gas Chromatography-Mass Spectrometry

HJ 77.4-2008 Determination of Dioxins Isotope Dilution High Resolution Gas Chromatography-High Resolution Mass Spectrometry

Solid Waste

HJ 963-2018 Determination of 47 kinds of pesticides such as organophosphorus by gas chromatography-mass spectrometry

HJ 951-2018 Determination of semi-volatile organic compounds-Gas chromatography-mass spectrometry

HJ 912-2017 Determination of Organochlorine Pesticides-Gas Chromatography-Mass Spectrometry

HJ 711-2014 Determination of phenolic compounds-Gas chromatography

water quality

HJ 894-2017 Determination of extractable petroleum hydrocarbons (C10-C40) by gas-chromatography

HJ 827-2017 Determination of carbamate pesticides by ultra-high performance liquid chromatography-triple quadrupole mass spectrometry

HJ 822-2017 Determination of aniline compounds-Gas chromatography-mass spectrometry

HJ 809-2016 Determination of nitrosamines by gas chromatography

ambient air

HJ 904-2017 Determination of polychlorinated biphenyl mixtures by gas chromatography

HJ 900-2017 Determination of Organochlorine Pesticides Gas Chromatography-Mass Spectrometry

HJ 646-2013 Determination of polycyclic aromatic hydrocarbons in gas phase and particulate gas chromatography-mass spectrometry

HJ 77.2-2008 Determination of Dioxins Isotope Dilution High Resolution Gas Chromatography-High Resolution Mass Spectrometry

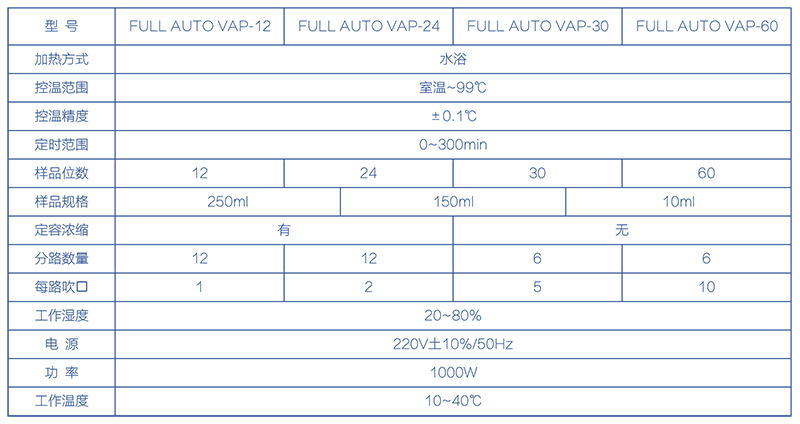

technical parameter

Company Profile

| Business Type: | Steel pipe production line, steel pipe embossing machine, steel pipe bending machine, steel plate embossing machine, steel plate bending machine | |

| Main Products: | ||

| Registered Capital: | 1000 ten thousand 人民币 | |

| Mode: | 贸易商 | |

| Area: | 天津 | |

| Size: | 1-49人 |

| Year of registration: |

2007

|